ZG2BD

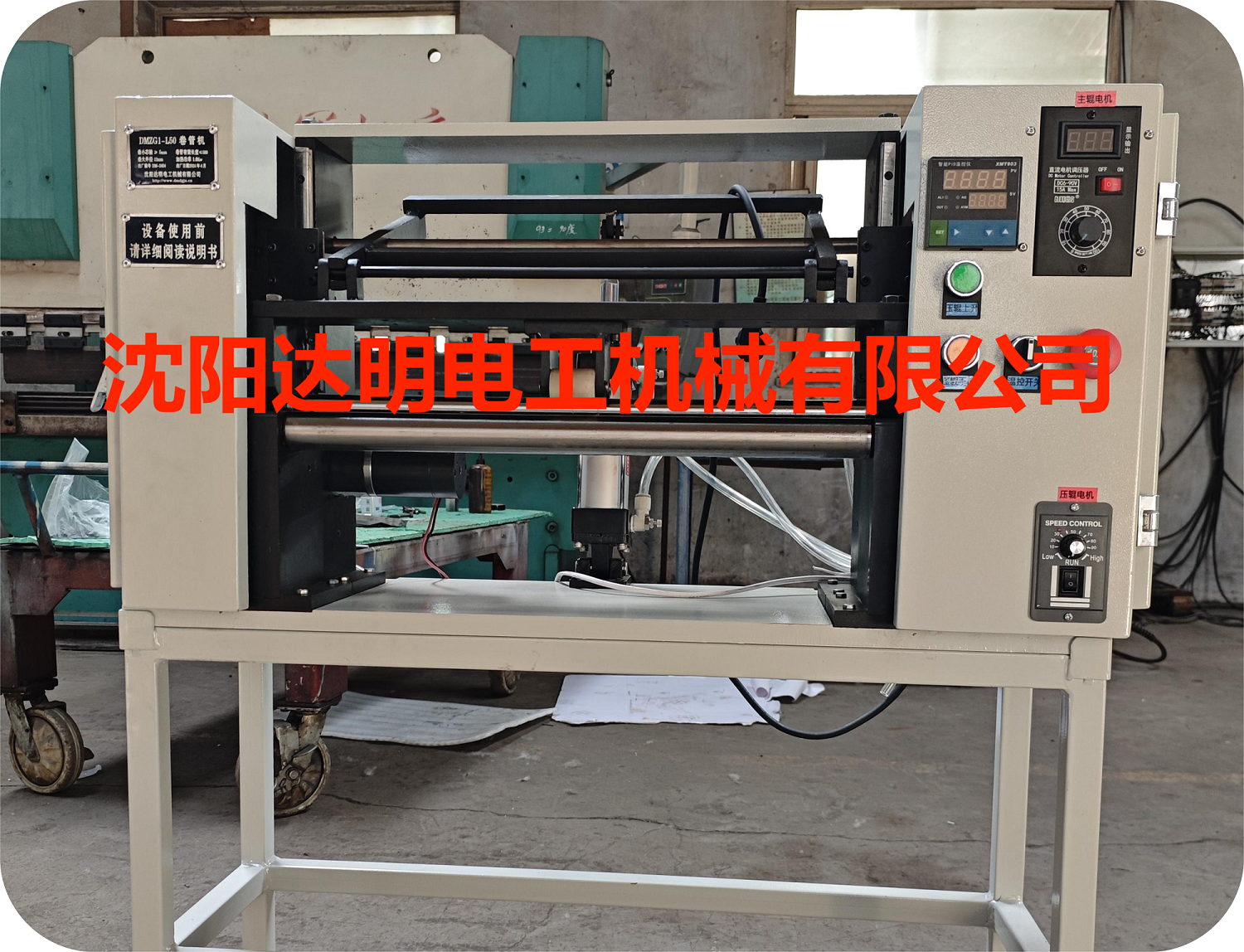

Insulation Winding Machine Series Description: This series of insulation winding machines is used for winding insulation paper (cloth) tubes, such as phenolic cloth tubes, phenolic paper tubes, epoxy glass cloth tubes, etc. It can also be used for the winding of special phenolic and epoxy products. With the development of modern technology, the application of insulation winding machines has become more widespread, such as in the winding of high-temperature tubes; high-temperature wear-resistant sealing gasket raw material tubes; and other fields requiring special tube winding. This series of insulation winding machines includes three-roller (four-roller) types: with front preheating rollers, front heating rollers, rear heating rollers, as well as front heating rollers, rear cooling rollers, large pressure rollers, and small pressure rollers (the small pressure roller is water-cooled). Both cold and hot rollers are made from special materials and manufactured through processes such as heat treatment to ensure long-term use without deformation, while also guaranteeing sufficient hardness on the working roller surface under conditions around 200°C. This ensures the quality of the wound tubes and the service life of the equipment. The pressure roller lifting can be done in two forms: mechanical chain lifting and pneumatic cylinder lifting. The table below shows our company's existing standard series products, which can also be designed and manufactured according to user needs. Equipment Model Winding Tube Diameter mm Winding Tube Standard Effective Length mm Winding Tube Line Speed Variable Frequency Speed m/min Hot Roller Surface Temperature Temperature Control Method Line Pressure N/cm ZG1E Φ6 (core) ~ Φ10 ≤160 ≤160 1~3 ≤180℃ ±5℃ Automatic ≥30 ZG1 Φ8 (core) ~ Φ40 ≤800 ≤800 1~5 ≤180℃ ±5℃ Automatic ≥30 ZG2A Φ16 (core) ~ Φ80 ≤1250 ≤1250 1~5 ≤180℃ ±5℃ Automatic ≥40 ZG2B Φ35 (core) ~ Φ200 ≤1250 ≤1250 1.2~6 ≤180℃ ±5℃ Automatic ≥50 ZG3 Φ80 (core) ~ Φ350 ≤1500 ≤1500 1.2~6 ≤180℃ ±7℃ Automatic ≥50 ZG6 Φ180 (core) ~ Φ800 ≤2000 ≤2000 1.5~7.5 ≤180℃ ±7℃ Automatic ≥60 ZG7 Φ300 (core) ~ Φ1500 ≤2000 ≤2000 1.5~7.5 ≤180℃ ±7℃ Automatic ≥60 ZG8 Φ800 (core) ~ Φ2000 ≤2000 ≤2000 1.5~7.5 ≤180℃ ±7℃ Automatic ≥60 Shenyang Daming Electric Machinery Co., Ltd.

- Product Description

-

AbsoluteYuanVolumeTubeMachineSystemSeriesSaidMing

The insulation winding tube machine is a specialized equipment for producing insulating tubes in the transformer manufacturing industry; such as producing: (phenolic cloth tubes, phenolic paper tubes, epoxy glass cloth tubes, etc., and can also be used for special purpose tubes, etc....Winding products).

With the development of modern technology, the application range of insulation winding tube machines is becoming more extensive; such as high-temperature and high-pressure tube winding; winding of high-temperature and wear-resistant sealing gasket raw material tubes; and other fields that require special tube winding, etc....All require this equipment.

This series of insulation winding tube machines all have: three-roller type (four-roller type including front preheating roller). Front heating roller, rear water cooling roller. The hot and cold rollers are cast from special materials and processed through technical treatment; they not only ensure long-term use without deformation but also guarantee sufficient hardness of the roller surface to produce more precise products. The size of the pressure rollers is water-cooled, and the cooling method is adopted according to customer process requirements. The temperature of the hot roller is displayed in dual control, measuring the surface and inner cavity temperature, and selecting the feeding form according to customer needs; front feeding integrated machine, rear feeding tension correction without feeding mechanism.The winding tube machine has added multiple functions..Please consult when ordering, and it can also be designed and manufactured separately according to user needs.

The following table lists our company'sProductionof insulation winding tube machine series products:

Equipment Model

Winding Tube Range (Minimum Core Maximum Outer Diameter, Unitmm)

Winding Tube Lengthand several specifications

Pneumatic动升降

Heating Method Oil Heating and Power

冷热辊 间距

备 注

机械升级

ZG1A

6-10

500

气动升降

电加热2KW

固定

ZG2A-L1250标准型

14-80

1050、1250、1550

气动升降

≧5KW

固定

如有变动

订货说明

ZG2A-L2000

16-80

1750、2250

定制选择

≧6KW

固定

ZG2B-L1500标准型

35-200

1050、1250、1750、2250

定制选择

≧5KW

手动可调

ZG2B(完全非标)

35-200(定制)

定制

定制选择

ZG3B-L1500标准型

100-350

1050、1250、1550

气动升降

≧7.5KW

电动可调

ZG3B-L2000

100-350

1750、1950、2250

机械升级

≧7.5KW

电动可调

ZG3C-L1500

90-420

1250、1550

气动升降

≧7.5KW

电动可调

ZG3(完全非标)

定制

定制

自定义选择

ZG6-L1800

100-800

1550、1950

机械升级

≧9.0KW

电动可调

ZG6(完全非标)

100-800

定制

机械升级

≧9.0KW

电动可调

ZG7-L1800

300-1000

1550、1950、2250

机械升级

≧12KW

电动可调

ZG7(完全非标)

300-1200

定制

机械升级

≧12KW

电动可调

Key words:

Get free product quotes

We will contact you within one working day. Please pay attention to your email.