And grease machine 150KG

- Product Description

-

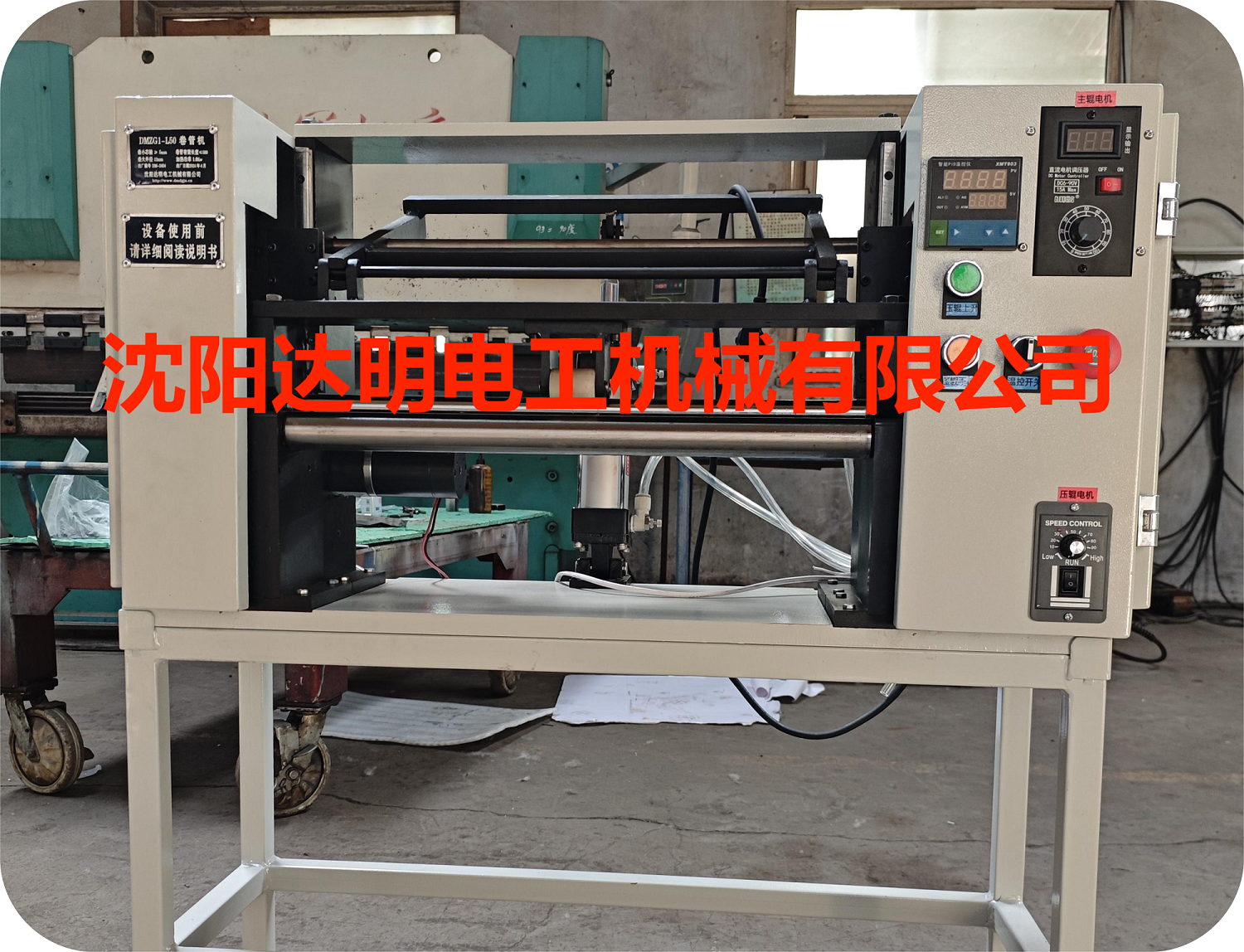

This series of equipment is used in the manufacturing process of lead-acid batteries and for lead paste preparation.

Our company can provide the following types of equipment:Also, we can design and manufacture specifically according to the user's needs.

Equipment Model Equipment Name

Batch and Paste Amount

Remarks

HG5A 5kg Paste Machine 5kg HG10A 10kg Paste Machine 10kg DL9907A

20kg Paste Machine

20kg

DL905A

50kg Paste Machine

50kg

QG961B

100kg Paste Machine

100kg

QG963B

200kg Paste Machine

200kg

Features of this series of paste machines: The paste barrel and stirring body are placed vertically, that is, vertical paste machines, with material added from the top and paste discharged from the bottom. The gap between the stirring blades and the barrel wall is small, preventing paste from sticking to the barrel wall during mixing. The barrel is equipped with a cooling water jacket, resulting in a lower outlet temperature for the lead paste. The original model of this machine is similar to the American 'Bull Head' brand paste machine. The paste machine consists of: motor, reducer, stainless steel inner and outer barrel, stirring body, base, cover plate, cooling water jacket, and electrical control box, etc. It has the following advantages:

a. All parts in contact with lead paste are made of high-quality stainless steel (1Cr18Ni9Ti).

b. The reducer is a 'quasi-hyperbolic gear reducer' with a large load capacity, and appropriate anti-acid measures ensure it does not corrode.

c. The configuration of the stirring blades is reasonable, ensuring uniform material turnover during the mixing process without dead corners. The transmission parts on the stirring body are sealed within the inner barrel, allowing for long-term use without acid corrosion. This also facilitates paste discharge and cleaning.

d. The paste discharge port is located at the bottom of the paste machine, and the door is locked during mixing.

e. The cover plate of the paste barrel has an acid addition port and a water addition port. Lead powder, acid, water, and additives are all added from the top of the paste machine. The acid addition port is funnel-shaped, with a shut-off valve below it. Below the shut-off valve are a rotating acid cup and an acid spraying pipe to achieve multi-point rotating acid addition.

Key words:

Get free product quotes

We will contact you within one working day. Please pay attention to your email.